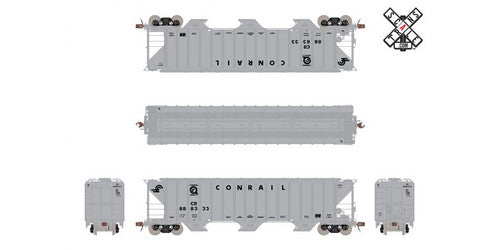

Scaletrains SXT33028 PS-2CD 4785cf Covered Hopper Conrail Quality #888333 HO Scale

Scaletrains SXT33028 PS-2CD 4785cf Covered Hopper Conrail Quality #888333 HO Scale is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

Scaletrains SXT33028 PS-2CD 4785cf Covered Hopper Conrail Quality #888333 HO Scale. Photos may show a different road number.

The PS-2CD 4785 Covered Hopper was a missing variation in the Pullman-Standard Covered Hopper family until now. The 4785s low side sill visually differentiates the carbody from its high sill siblings (4727, 4740, and 4750). Since the 1960s, these cars have crisscrossed North America in singles and groups of hoppers. Our Rivet Counter series model feature numerous roof hatch, outlet gate, running board, and end “cage” support variations per railroad, road number, and era.

Road Number Specific ScaleTrains

- Era: mid 1990s to mid 2010s

- Series 886826 to 887025, 888254-888366, Class 138H, built 9-10/67

- Fully-assembled

- Multiple road numbers

- Each road number features different data and stenciling differences including Light Weight designations

- Body with tall end supports and no shear plates

- Factory-applied ladders with metal rungs

- Handbrake mounted to tall end supports

- Photo-etched stainless-steel see-through Apex (slotted) walkway with metal grab irons and coupler crossover platforms

- Continuous replacement fiberglass trough loading hatches

- Short center sill

- Miner Mark E-7717 gravity outlet gates

- Factory-applied metal grab irons, coupler cut levers, and trainline hoses

- Brake plumbing with separate air reservoir, control valve, and retainer valve plus separately applied wireform plumbing including trainline pipe

- Durable die-cast metal semi-scale standard Type E couplers

- Highly-detailed Barber S-2 100-ton trucks with finely rendered raised foundry data, rotating bearing caps, side bearing detail, and truck-mounted brake beams

- Reporting mark and road number stenciled on each truck sideframe

- 36” machined metal wheels with accurately profiled .110" wide wheel tread

- Operates on Code 70, 83 and 100 rail

- Weighted to Industry standards for reliable operation

- Printing and lettering legible even under magnification

- Paint colors match Tru-Color Paint color: TCP-172 weathered concrete

- Packaging safely stores model

- Minimum radius: 18”

- Recommended radius: 22”

One of the larger sizes offered in the Pullman-Standard covered hopper catalog, the PS-2CD 4785 cubic foot design could be optimized for a variety of commodities, from grain products, to chemical or mineral ladings. Introduced in 1967 and built at their Butler, PA plant, the basic design would see refinements to its basic design over its five-year production span. The end “cages” of the cars would change over this period, with revisions to the end grab iron and support arrangements. Later production would also feature tall shear plates as part of the end sills, adding another visual distinction to this family of cars.

And as common with other covered hopper production, the customer could option the cars with different roof hatch options; full-length trough, three-trough, or round hatches. The full-length trough hatches were typically applied to cars intended for grain duty, allowing easy loading from spouts used at grain elevators. Round hatches are easier to seal, and were preferred for cars designed for commodities that needed better protection from the elements. The three-trough option, unique to Cotton Belt, was essentially the full-length trough divided into three smaller sections, making it a “best-of-both-worlds” option that combined the ease of loading of the full-length trough, with the better sealing capability of a round hatch.

Different outlet types and brands could also be fitted, with gravity or gravity-pneumatic types installed for optimal handling of different commodities. Gravity outlets were preferred for grains, while the gravity-pneumatic outlet type offered greater flexibility in the types of commodities that could be handled. The gravity setting allowed the commodity to discharge from the outlets via normal gravity (such as grain), while the pneumatic setting allowed commodities to be unloaded via vacuum hose. This was used for ladings such as plastic pellets, or powdery chemical or foodstuff commodities, that would tend to “cake-up” in the outlet, and needed the vacuum for smoother and contamination-free unloading. Running board and end coupler platforms could also vary per customer option, with Apex (slotted-hole), Morton (round-hole), and U.S. Gypsum (diamond-hole) types seen fitted to these cars.

Specifications

Specifications

-

Scale

-

Product Type-

-

Height

-

Width

-

Depth