NixTrainz Loco Lights - NTZ103 Finished Assemblies (Scale=HO) #NIX-LocoLightsFinishedAssemblies

NixTrainz Loco Lights - NTZ103 Finished Assemblies (Scale=HO) #NIX-LocoLightsFinishedAssemblies is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

Nixtrainz Loco Lights - NTZ103 Finished Assemblies (Scale=HO) #NIX-LocoLightsFinishedAssemblies

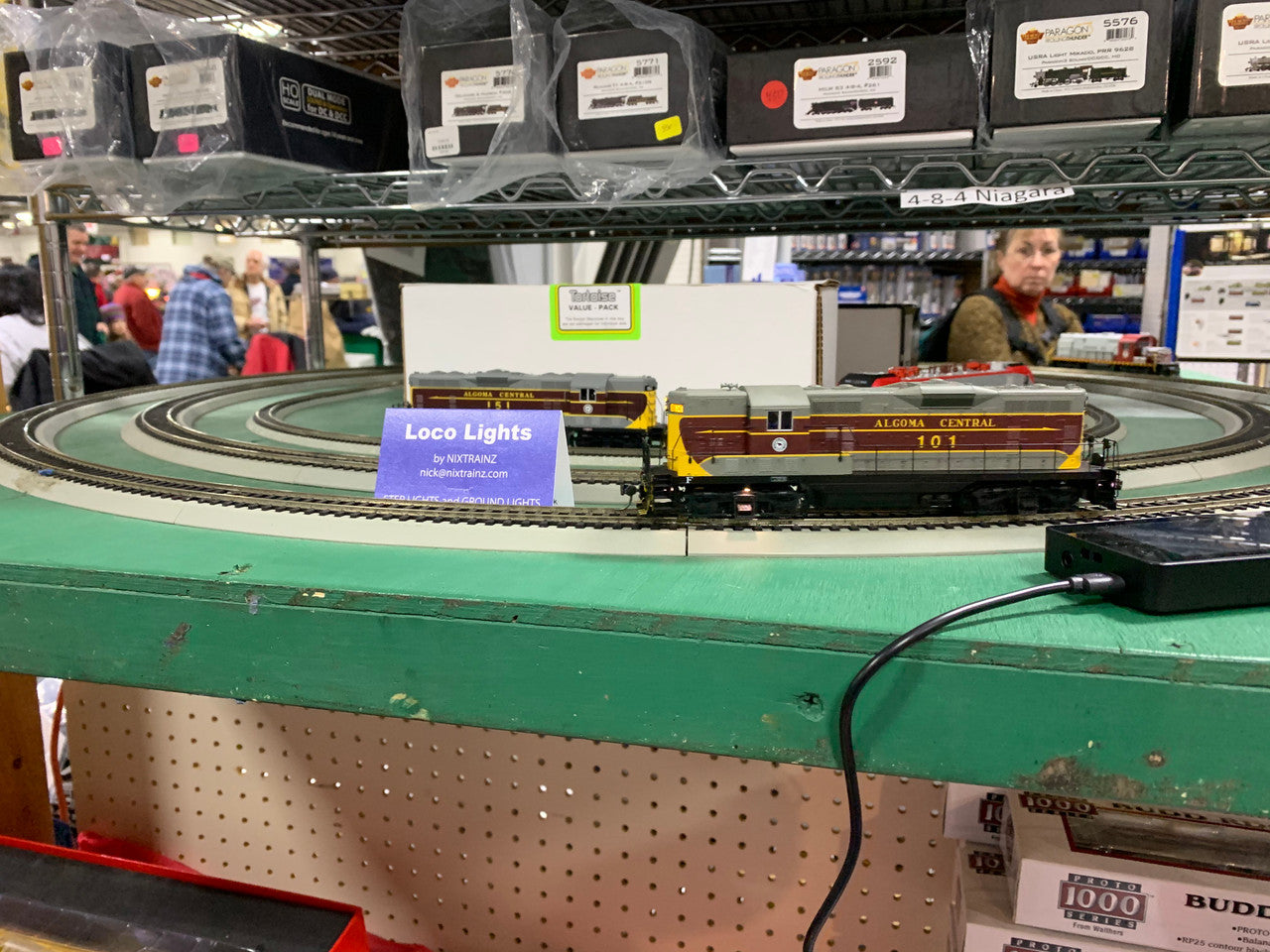

*** Pictures of the Algoma Central locomotive show the Loco Lights - Finished Assemblies installed on my locomotive. ***

Finished Assemblies

4 Finished Step Lights and 2 Finished Ground Lights.

Included are 2 Ground lights and 4 Step lights. Glue them on your model, solder in the wires, program them on your decoder and run!

A PROCEDURE FOR ASSEMBLY OF GROUND AND STEP LIGHTS

Assembly Instructions

This is the procedure I’ve worked out so far. It may well modify itself with time. So far I’ve made a couple hundred finished fixtures. Your input is appreciated too!

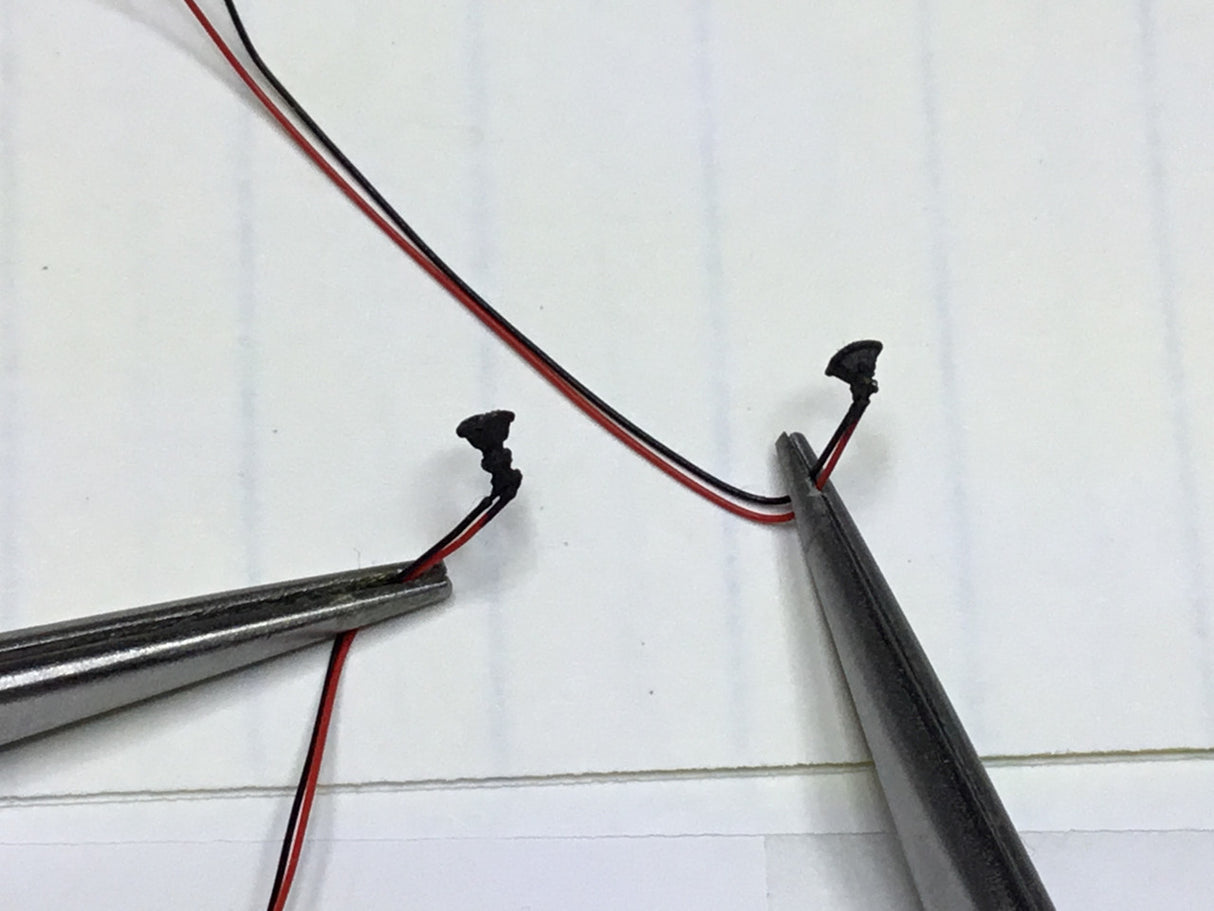

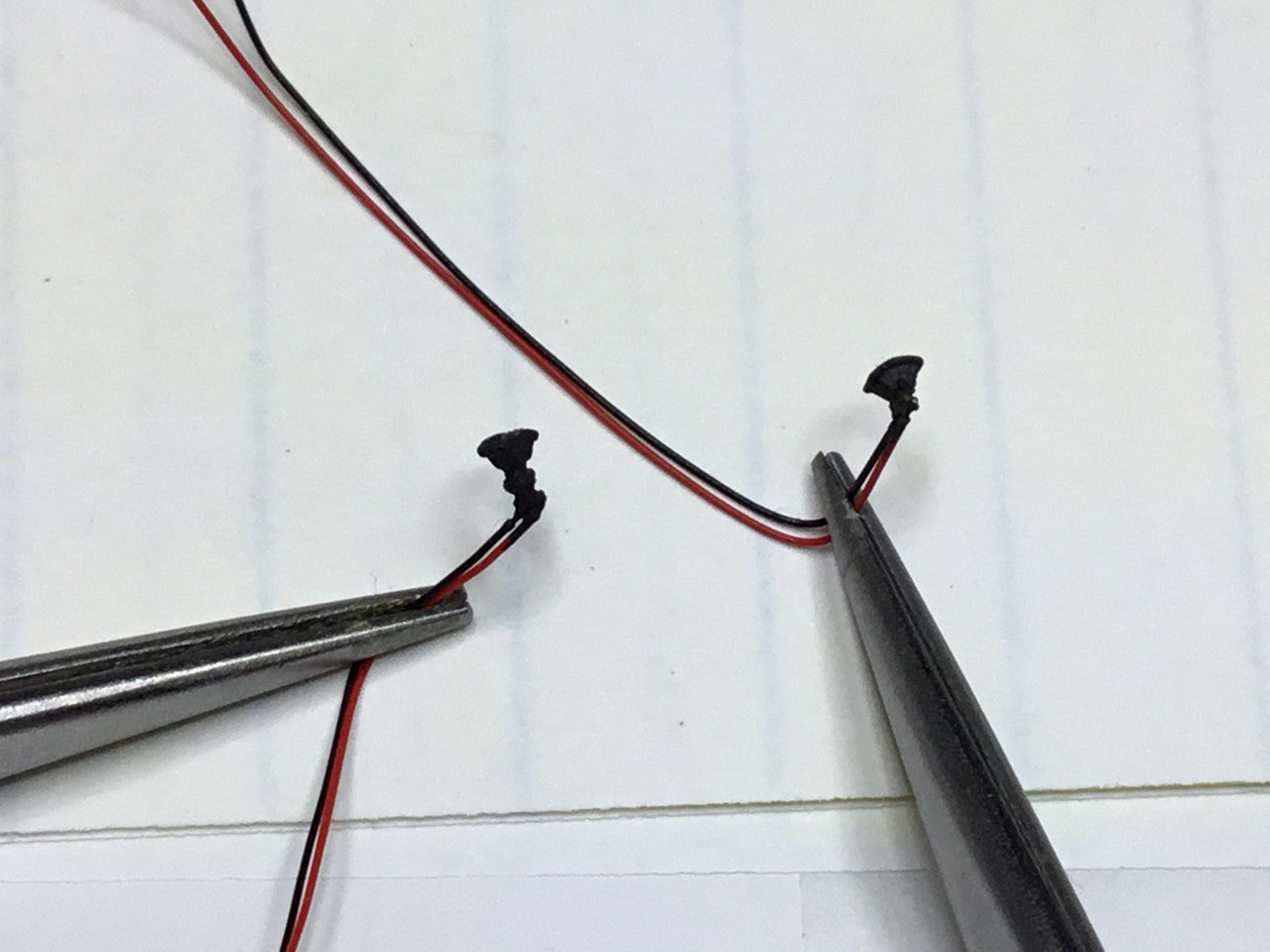

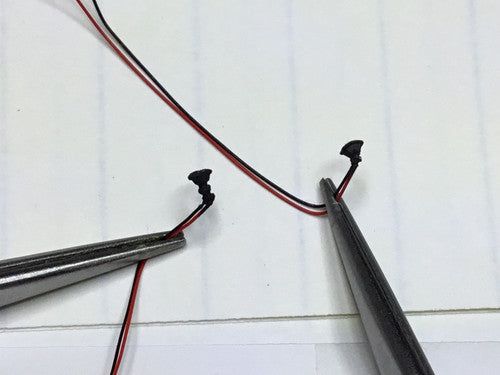

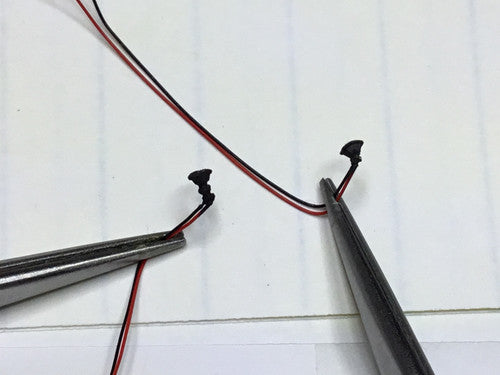

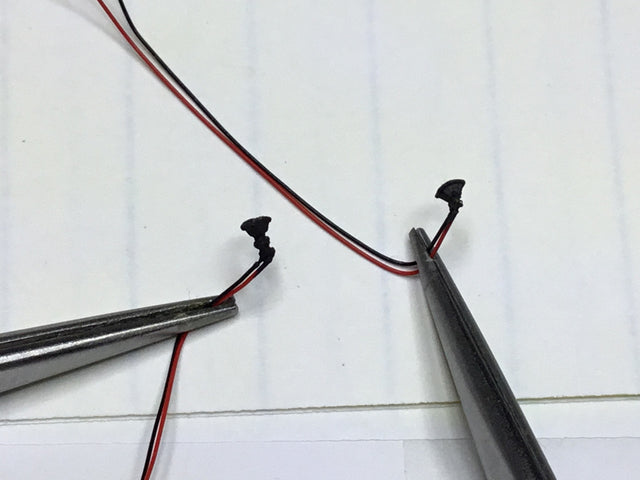

The light bulb side of the fixture is pointing up from the sprue. If desired, test fit the fiber optic into the fixture. You may or may not need to clean out the hole through the fixture with a #80 drill. The hole is 0.0135” and the fiber optic strand is 0.010”. Lately I’ve been dipping the end of the fiber optic strand into a pool of CA then pushing it down through the hole in the fixture. This fixes the two parts as they will be assembled as well as makes the fixture a little more manageable. Cut the fixture from the sprue. I’ve started to use a sharp knife to make this separation as clean as possible. Alternatively, insert the fiber optic strand now so it extends past the end of the base of the fixture slightly. In the past when some of the fixtures have broken off I’ve found its possible to shave off the bit of sprue when holding the fixture between thumb and forefinger with minimal loss of blood.... Trim the bottom of the fixture to the desired length. For this a flush cutter, sprue nipper or sharp knife leaves a good surface for a joint. I prefer cyanoacrylate (CA) to attach the fixture to the LED. Carefully dip the bottom of the fixture into a drop of CA, touch it to a dry spot to remove the excess then place on the LED. Hold in position on the LED until stable. If I had more hands now would be a good time for a kicker to accelerate the bond. After the CA has had time to cure it is time to cut the fiber optic strand from the lighting end of the fixture. The next step is to paint it black or opaque where the light is not wanted. I am using cheap Walmart acrylic craft paint at the moment. I’ve found that a second coat of paint is necessary to stop all the unwanted light from escaping. I test for light leaks with a 9 volt battery which has a 1K resistor in line attached while adding the second coat of paint. Allow the paint to dry thoroughly.

I would attach the assembly to the locomotive with GOO, rubber cement or your preference for possible removal in the future. I generally hold routed wires in place with GOO or rubber cement. When supplied, the 0402 warm white LEDs are standard color coding for connection to power. If the light is too blue or purple a little Tamiya Clear Orange might warm up the color. A number of the prototype locomotives I’ve photographed lately are using LED bulbs so color to your taste...

I’ll post further tips on the website as they become known.

Enjoy!

Specifications

Specifications

-

Scale

-

Product Type-

-

Height

-

Width

-

Depth