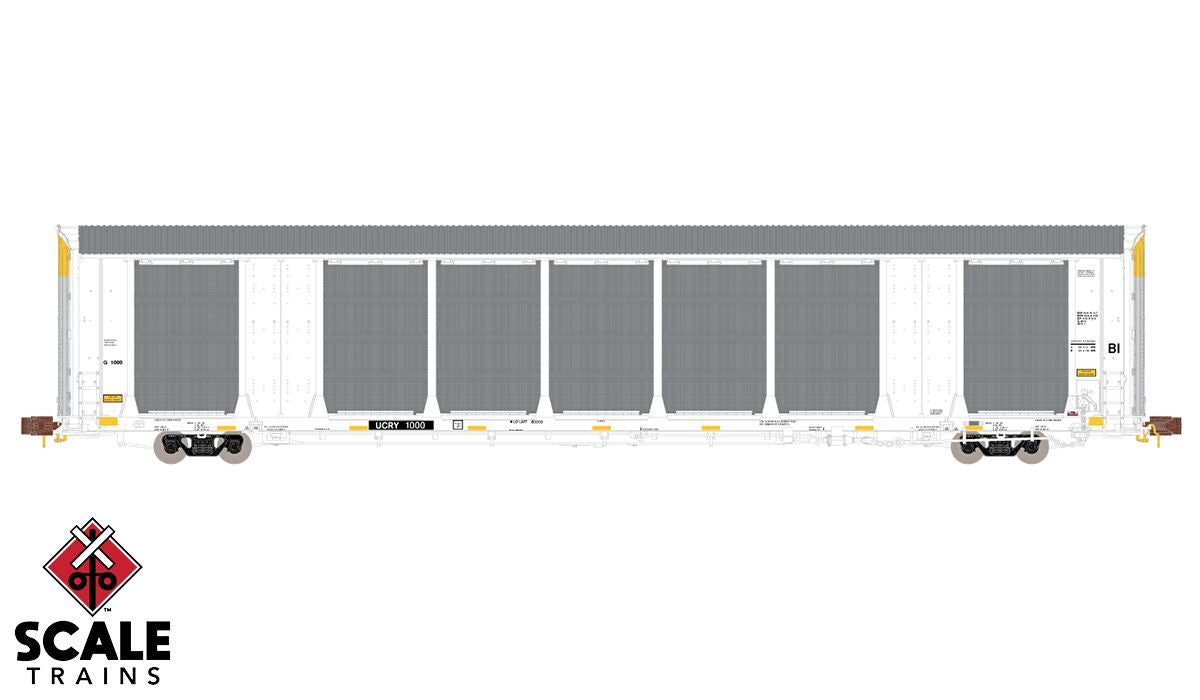

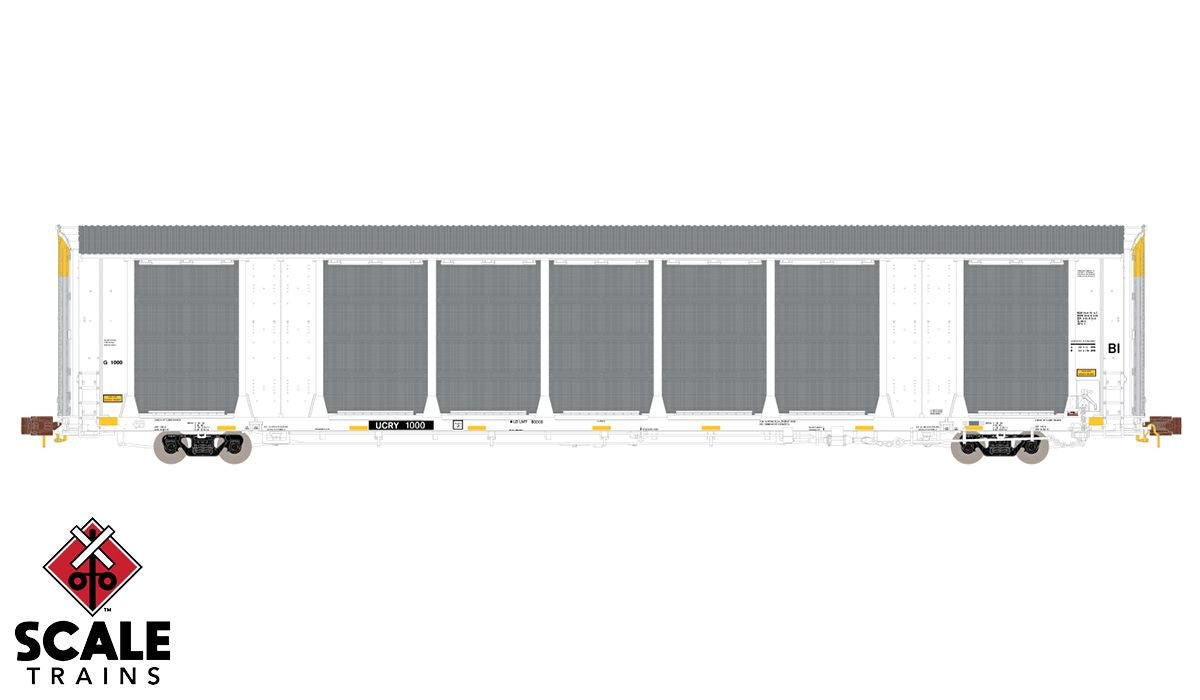

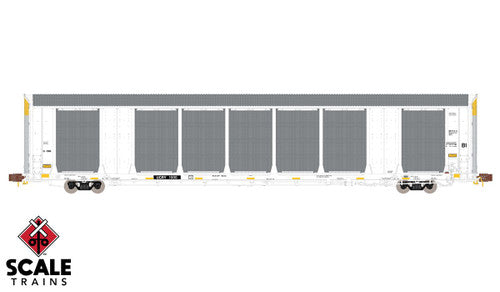

Scaletrains SXT33764 Gunderson Multi-Max Autorack, Utah Central Railway/White/UCRY #1057 Rivet Counter N Scale

Scaletrains SXT33764 Gunderson Multi-Max Autorack, Utah Central Railway/White/UCRY #1057 Rivet Counter N Scale is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

Scaletrains SXT33764 Gunderson Multi-Max Autorack, Utah Central Railway/White/UCRY #1057 Rivet Counter N Scale (Picture may show a different Road Number).

With several thousand auto carriers built for nearly all North American Class One railroads since 2014, the Greenbrier/Gunderson Multi-Max has become the premier auto carrier design of the 21st century. Many of these cars wear colorful paint schemes and feature large logos which help them stand out alongside older autorack designs.

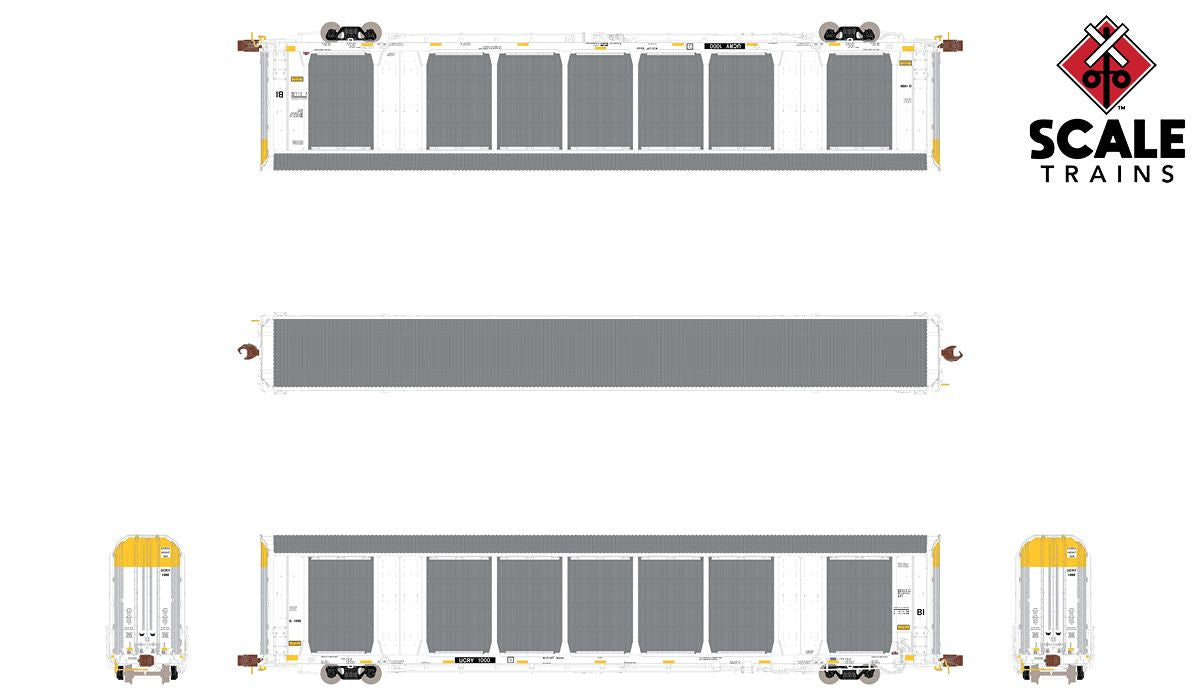

Our N Scale Rivet Counter series Multi-Max Autorack features maximum detail. Railroad, road number, and era specific details include four (4) body variations; three (3) ladder styles; two (2) types of end doors; separate end door rods; three (3) end sill configurations; two (2) different upper and lower side panel mountings; inside or outside mounted brake cylinder, brake beam, and brake rod support mounting brackets; and much more.

Road Number Specific ScaleTrains

- Era: 2018 to Present

- UCRY Series Unknown, built 3/18 – 4/18

- Stenciled BI for bilevel

- Late version

- Fully assembled

- Multiple road numbers

- Factory-applied metal grab irons, coupler cut levers, and trainline hoses

- Intricate brake plumbing

- Body-mounted semi-scale Type E lower knuckle couplers – Micro-Trains® compatible

- Upper side panel mounting with three (3) outside mounting tabs and no strip

- Lower side panel mounting with four (4) lower recessed tabs and ¾ width strip

- Late end doors with “zig-zag” angle panels

- End sill step, end sill grab irons and side sill grab irons

- Low mounted side ladders

- Outside side sill brake cylinder and brake beam mounting brackets

- Outside side sill brake rod support brackets

- Paint colors match Tru-Color Paint color: roof and side panels TCP-354 galvanized steel

- 14 finely molded corrugated side panels

- Rivet details on colored panels represent either bilevel or trilevel versions

- Correct ASF low deck swing motion trucks

- 28” machined metal wheels

- Highly detailed underbody brake system with wire form brake rods and air line plumbing, photo etched metal brake rod and air line plumbing support brackets; plastic brake beams, air reservoir, brake cylinder, control valve and retainer valve

- Printing and lettering legible even under magnification

- Weighted to Industry standards for reliable operation

- Operates on Code 55 and 70 rail

- Clear jewel box packaging safely stores model

- Minimum radius 11”

- Recommended radius 19”

All Rivet Counter Freight Cars Feature

- Fully assembled

- Multiple road numbers

- Factory-applied metal grab irons, coupler cut levers, and trainline hoses

- Intricate brake plumbing

- Body-mounted semi-scale Type E lower knuckle couplers – Micro-Trains® compatible

- Printing and lettering legible even under magnification

- Weighted to Industry standards for reliable operation

- Operates on Code 55 and 70 rail

- Clear jewel box packaging safely stores model

Since the development of the automobile, railroads and automakers have worked together to develop better and more efficient methods for transporting new vehicles to market. Shipping via rail offers automakers a fast, cost-effective method of moving new autos from manufacturing centers to distribution centers, or in the early days, to dealers themselves.

Double-door boxcars were amongst the first designs to haul automobiles. The larger opening of the double-doors allowed cars to be driven aboard. As time passed, flatcars equipped with multi-level open-air racks were developed. Since automobiles are relatively light, long flats of up to 89’ in length were adapted to use two (bi-level) or three (tri-level) deck racks. Simply known as “autoracks”, these unique cars can carry a dozen or more vehicles.

By the late 1960s, new vehicles shipped via racks would prove too tempting for vandals who used the windows on new vehicles for target practice. Thieves would also take a toll by breaking into new automobiles to steal high-value components like stereos and hubcaps. Even train-hopping transients would prove to be a problem since riding in a new automobile was much more comfortable than a dirty boxcar or gondola.

To shield new vehicles from wayward projectiles, railroads and car builders added metal screens or fiberglass panels to the sides of the autoracks. While the side screens or panels worked to protect window glass, the ends of the autoracks remained open which allowed easy access for thieves or transients to climb aboard and damage new vehicles.

The 1970s would see the development of fully-enclosed autoracks to protect the valuable cargo inside. The sides were completely protected with perforated galvanized-steel panels. The top of the car was enclosed with a galvanized steel roof which protected cars on the top level. Finally, the ends were equipped with a large pair of sliding or folding doors to keep unwanted passengers out.

With many racks built in the 60s and 70s nearing the end of their operational lives, Greenbrier/Gunderson introduced a new design in 2013 to provide the ultimate in protection for vehicles as well as operational flexibility. The new design, dubbed “Multi-Max”, introduced design elements to help meet the challenges faced by railroads and shippers in the 21st century.

While the basic enclosed autorack protected new autos from projectiles, a new form of vandalism became prevalent in the late 1990s, graffiti. Paint spray would pass through the perforations in the side panels and onto the new automobiles ruining their finish. The perforations are a necessity because hey allow enough light for workers to see while loading or unloading the cars as well as to allow ventilation of automobile exhaust. Multi-Max features smaller, fewer, and more widely spaced perforations in its side panels, reducing the chance of paint spray passing through.

In another novel design feature, the cars feature the ability to adjust the number of decks. “Bi-level” autoracks are intended to carry taller vehicles, such as SUVs or vans, while “tri-level” autoracks, having an additional deck, handle shorter-in-height standard or compact autos in the same given space. Traditionally, railroads would order bi- and/or tri-level racks based upon anticipated traffic from manufacturing plants. If a plant decided to shift production from one vehicle type to another, such as from automobiles, to SUVs, it could result in a surplus of a car type unsuitable for the new traffic. Multi-Max features the ability for railroad car shops to change the car configuration from bi-level to tri-level, or vice-versa, as traffic patterns dictate.

With several thousand auto carriers built for nearly all North American Class One railroads, the Gunderson Multi-Max has proven to be an extremely popular design. In a welcome departure from recent practice, many of these cars wear colorful schemes featuring large logos which helps them stand out in a train alongside older autorack designs. With the numbers built to date and its popularity with shippers, the Greenbrier/Gunderson Multi-Max is poised to become the premier autorack design of the 2000s.

Specifications

Specifications

-

Scale-

-

Product Type-

-

Height

-

Width

-

Depth